hte for sustainable resources

PROCESSING

FEEDSTOCKS FROM

RENEWABLE & RECYCLED

MATERIALS

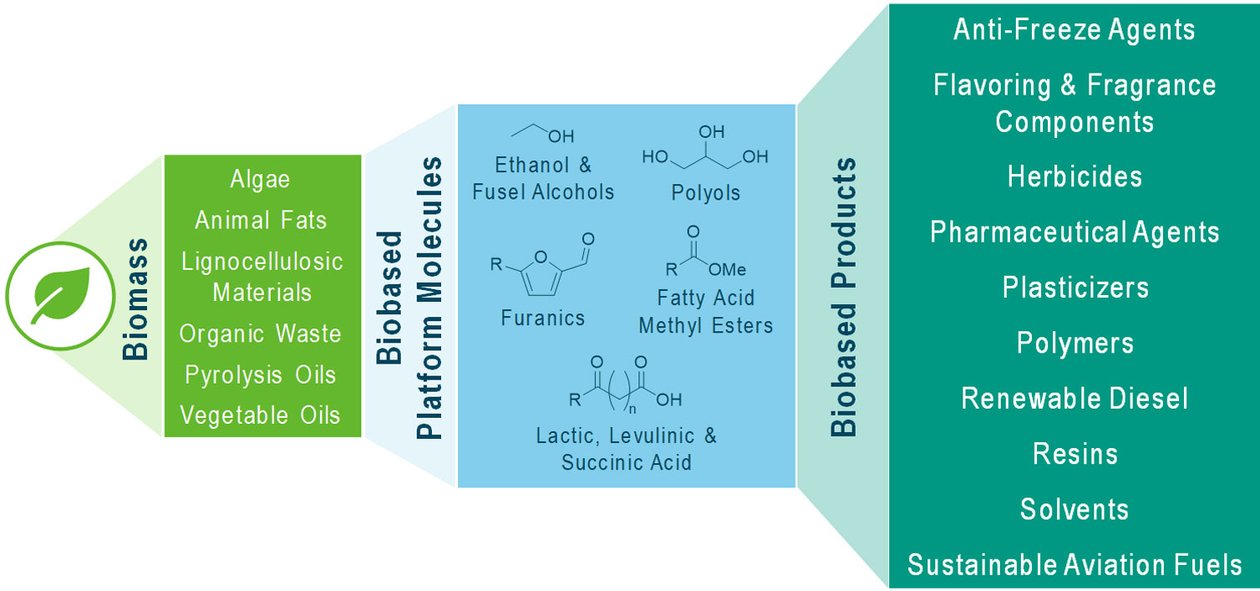

Novel processes for obtaining high-value products based on feedstocks from renewable and recycled materials are very important, as they allow the use of sustainable resources and support a circular economy. The goal is to reduce carbon footprint and to open new pathways to platform chemicals and drop-in fuels.

High Throughput Experimentation (HTE) has proven the most efficient tool to accelerate the development of new catalytic processes and to ensure a short time to market for renewable products.

OUR SOLUTIONS

- Processing and screening of various feedstocks gained from renewable & recyclable materials

- Supporting process optimization and feedstock evaluation (e.g. co-processing)

- Upscaling from batch to continuous process

- Catalyst synthesis and characterization from powder to commercial shapes

- Offline and online analytics, including method development and separation techniques

YOUR BENEFITS

- Short time to market for new products and processes

- Evaluate processability of new feedstocks

- Testing support for industrial operation

(e.g. troubleshooting) - Independent and customized R&D services with excellent track record in catalyst synthesis and testing

LIGNOCELLULOSE

CELLULOSE

HEMICELLULOSE

LIGNIN

CARBOHYDRATES

SUGARS

ALGAE OIL

PYROLYSIS OIL

PLASTIC WASTE

ANIMAL FATS

VEGETABLE OILS

BLACK LIQUOR

Biomass offers unique opportunities to create valuable products

hte is your partner for decreasing your time to market for new products based on feedstocks from renewable and recycled materials.

Success stories from our projects

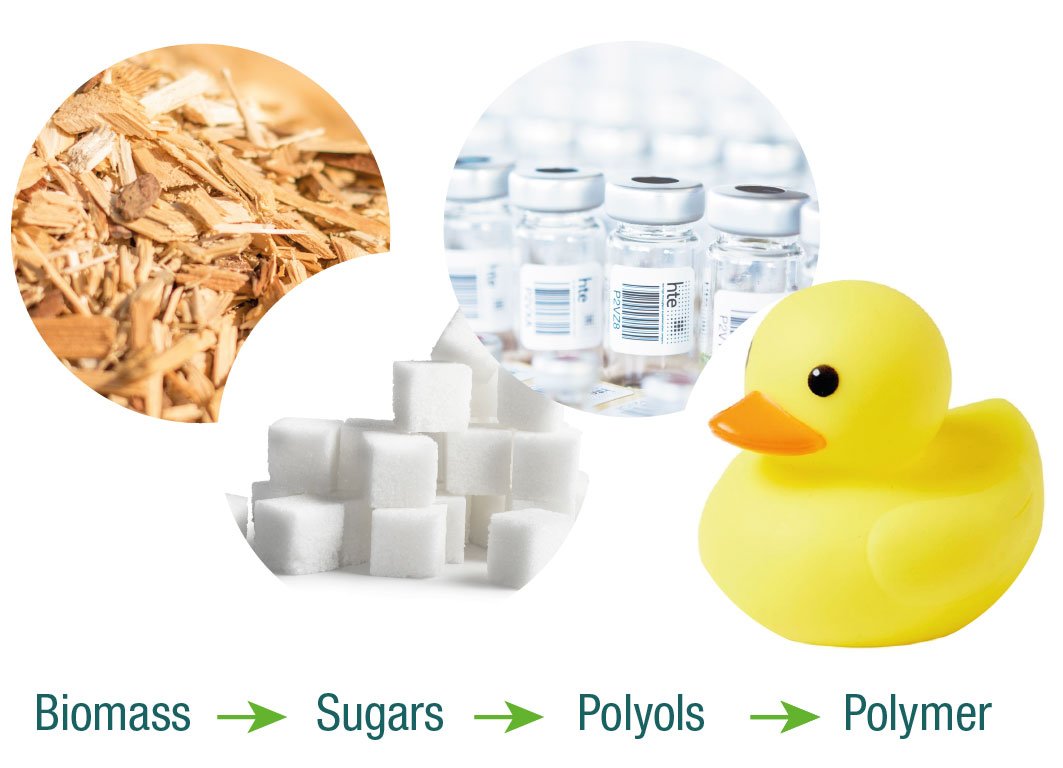

FROM BIOMASS TO “GREEN” NYLON

hexanediol using a new catalytic process; a key monomer for polyamide 6.6 known as nylon. The entire process was successfully developed at hte. It includes:

- Synthesis and screening of 500 catalysts

- 26 test runs with 16-fold HTE unit

- Upscaling of 44 catalyst formulations

- Screening of 30 feed blends in 8-fold

bench scale unit

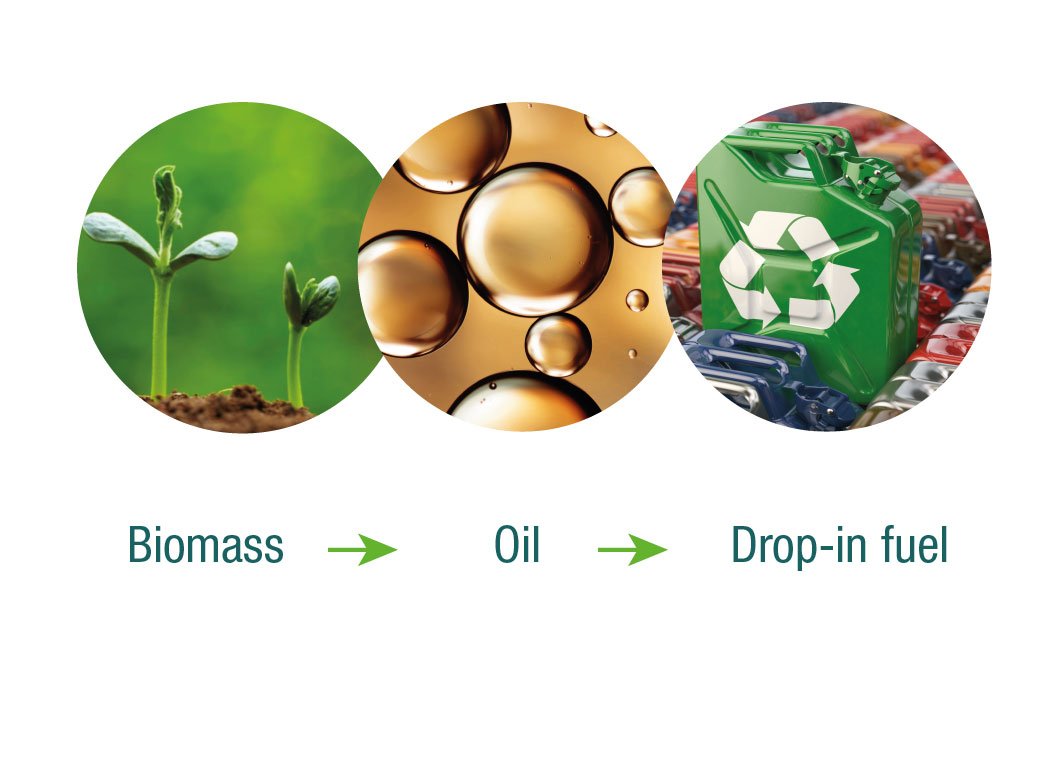

HYDROTREATED VEGETABLE OIL AS DROP-IN FUEL

Feedstock, such as vegetable oil, can be upgraded by catalytic hydrogenation. In this catalytic process, the feedstock is converted into long-chain hydrocarbons, which can be used as drop-in fuels and kerosene.

In this project, a test system with 16 parallel reactors and small amounts of catalyst were successfully applied for testing a commercial hydrotreating process for converting rapeseed oil into drop-in fuel.

Our hte technologies have an excellent track record for processing 1st, 2nd and 3rd generation bio-oils.

Broad range of technologies under one roof

For our partners and customers, we offer under one roof a broad range of parallelized & automated technologies in our portfolio to utilize renewables: from multifold batch, to multifold gas phase and trickle-bed reactor systems, parallelized bench scale systems, to our novel short-contact time testing technology, like our proprietary fluidized bed testing systems. Our portfolio of technologies enable processing from feedstocks as simple as CO2 to ones as complex as lignin and cellulose. The list includes also carbohydrates, sugars, algae oil, fats alongside many more.

Q&A Section

It is of high value to incorporate real industrial feedstocks early in the laboratory phase to ensure an industrially relevant development work and to minimize unforeseen surprises during consecutive piloting phase.

From a technically viewpoint, high throughput units are very well suited to operate with real industrial feeds, however this fully depends on the type & condition of the feed and the reaction pathways towards fine chemicals.

For a thorough process development, we recommend starting with a model feed compound or blends prior processing of real industrial feed. The benefits are:

- a model feedstock gives insight into the basic reaction kinetics, as well as the intrinsic activity and selectivity of the active materials.

- the comparison between model feed and real feed gives valuable insights about impurities in the real feed that will impact catalyst activity and stability (e.g. poisoning, deactivation, corrosion).

Additionally, a possible pre-treatment step or enhancements of the real feed can be considered to upgrade the material and improve catalytic performance (e.g. filtration, distillation, pH adjustment, halogen removal).

If you have limited research resources, but you want to shorten your learning curve and speed up your time to market you might consider utilizing external service expertise. This will also provide you with a high level of flexibility.

Our R&D services offer you always access to various state-of-the-art testing technologies and highly experienced project teams. As an independent service provider, we don't have stakes in catalysts or process IP development. So, we can also test and benchmark commercial catalysts in a competitive catalyst testing for you.

Customers with a full research pipeline and dedicated, well trained lab teams often decide to buy their own high-throughput experimentation systems including digital software solutions.

- Hydro-processing of triglycerides cause high consumption of hydrogen and therefore the process is limited to hydrogen compressor capacity. When triglyceride are mixed with the diesel or LGO, hydrogen consumption will be significantly lower and the process will be more controllable.

- Hydrogenation of triglycerides is an exothermic process. This means by using triglycerides more heat will be generated causing hydrocracking rather than HDO/-CO2 and therefore can affect the yield negatively. By using a 80:20 or 85:15 blend the exotherm can be controlled better and heat exchange is more efficient.

- Hydro-processing of triglycerides will results in C17 and C18 products and therefore co-processing of triglycerides with diesel or LGO will lead to an increase in the Cetan number directly. In the other hand, using 100% triglycerides to produce renewable diesel still requires further treatment beside HDO/-CO2. The additional process could include hydrocracking or hydro isomerization.

CONTACT US

Dr. Fabian Schneider

Head of Business Development

T +49 6221 7497 524

E Fabian.Schneiderhte-company.de