Parallel testing technologies

Welcome to the world's largest high throughput laboratory for catalysis R&D

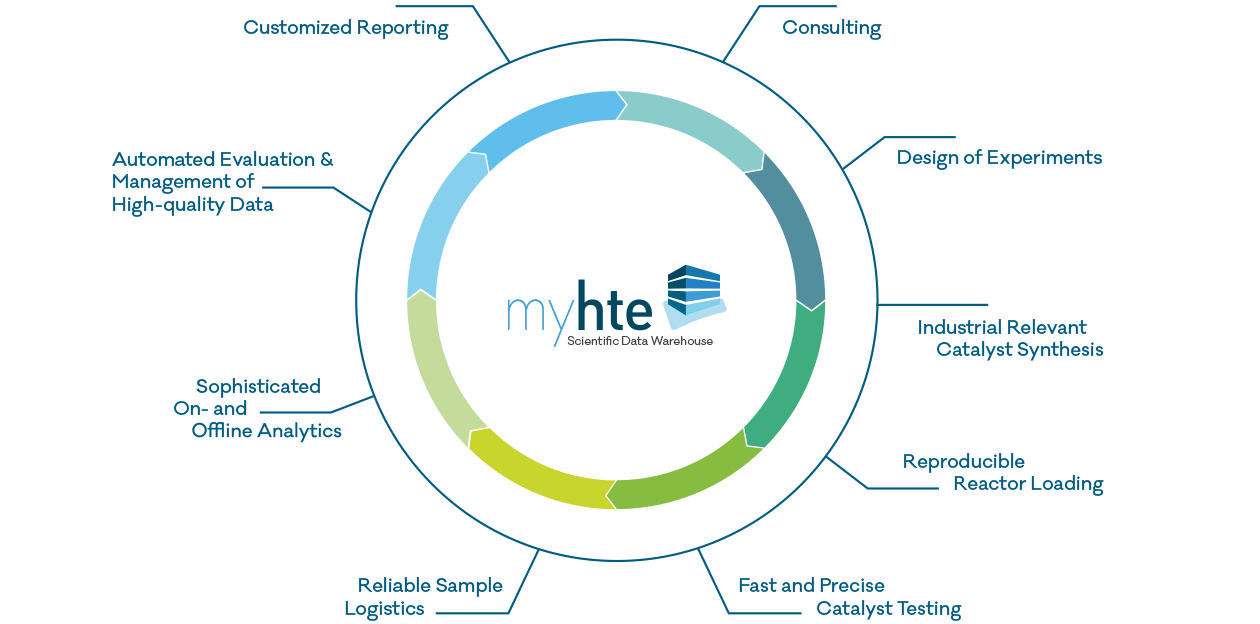

Over 9,000 m² of laboratory, workshop, and office area enable us to offer our customers the ideal research environment for High Throughput Experimentation. With our experts, technology, and our unique Software Solutions we support our customers in each step of the catalyst testing workflow. In R&D Solutions we offer services from scientific consulting up to customized reporting. Within Technology Solutions we deliver all necessary hardware and software equipment for an end-to-end Lab 4.0 solution. In this way, customers benefit from speeding-up their catalysis R&D.

Competencies within the complete catalyst testing workflow

At hte, all of the independent variables, process parameters, and analytical values are stored in the myhte™ database. All dependent variables can be calculated and used for reporting. Since all information of the experiment is stored, any report formats can be agreed with the customer and all independent and dependent variables can be used for plotting.

All steps of the high throughput workflow are supported and enabled by hte’s software solution myhte™. The powerful data management software retrieves, integrates, stores, and enables the user to analyze and visualize the data generated within the workflow. It connects huge amounts of online and offline analytical data with experimental context and synthesis parameters in one database, allowing the researcher to optimize the design of the experiment in the next workflow step.

Using high throughput methodologies generates large numbers of samples which need to be analyzed fast. hte’s analytic team develops and provides robust and reliable analytical methods for online and offline analytical instruments which are fully integrated into myhte™.

In the course of an experiment thousands of online gas-phase samples and hundreds of liquid samples are produced. All samples have a time stamp with respect to the experimental time on stream. Liquid samples and their derivatives are tracked by bar codes within myhte™ and sent to different offline analyses instruments.

Consulting comprises hte's capability to apply high throughput experimentation to the most challenging projects in industrial catalysis. hte's experts are combining an outstanding expertise in many scientific and technical fields around catalysis, as e.g. materials sciences, industrial process know-how, engineering & construction, analytics, data evaluation, and many more.

High Throughput Experimentation in many cases is the door opener to apply a rational design of experiments as well as statistical methods, e.g. full factorial designs or others, of planning and evaluating large sets of experiments. It is suitable for catalyst synthesis and performance testing. With e.g. 16- or 48-fold reactors 16 or 48 catalytic materials can be explored with smart statistical designs in one single experiment.

Handling large numbers of catalyst materials is a challenging task. Their composition, preparation, shaping, and reactor loading method strongly influence the performance of the catalysts. At hte, we offer unique synthesis services for materials formulation, catalyst shaping, characterization, and reactor loading.

The loading of reactors represents the interface between catalyst production and testing. It is an interdisciplinary field that combines mechanical, chemical, and administrative aspects. The entire process cycle is covered at hte: from loading and removal of the catalysts in the reactors, through cleaning and quality control, up to maintenance of the reactors.

For the discovery and optimization of catalysts, we carry out catalyst testing projects on our reliable reactor systems. The systems are fully supported by hte's software solutions, enabling our customers to realize the productivity benefits of high throughput technology. A dedicated process control suite, hteControl™, provides the flexibility to execute complex experimental protocols, including demanding activation procedures, and allows unattended 24/7 operation of the unit over multiple months.