Micro Downflow Technology

Test catalysts and feeds for Fluid Catalytic Cracking (FCC) under relevant process conditions but with laboratory scale budgets

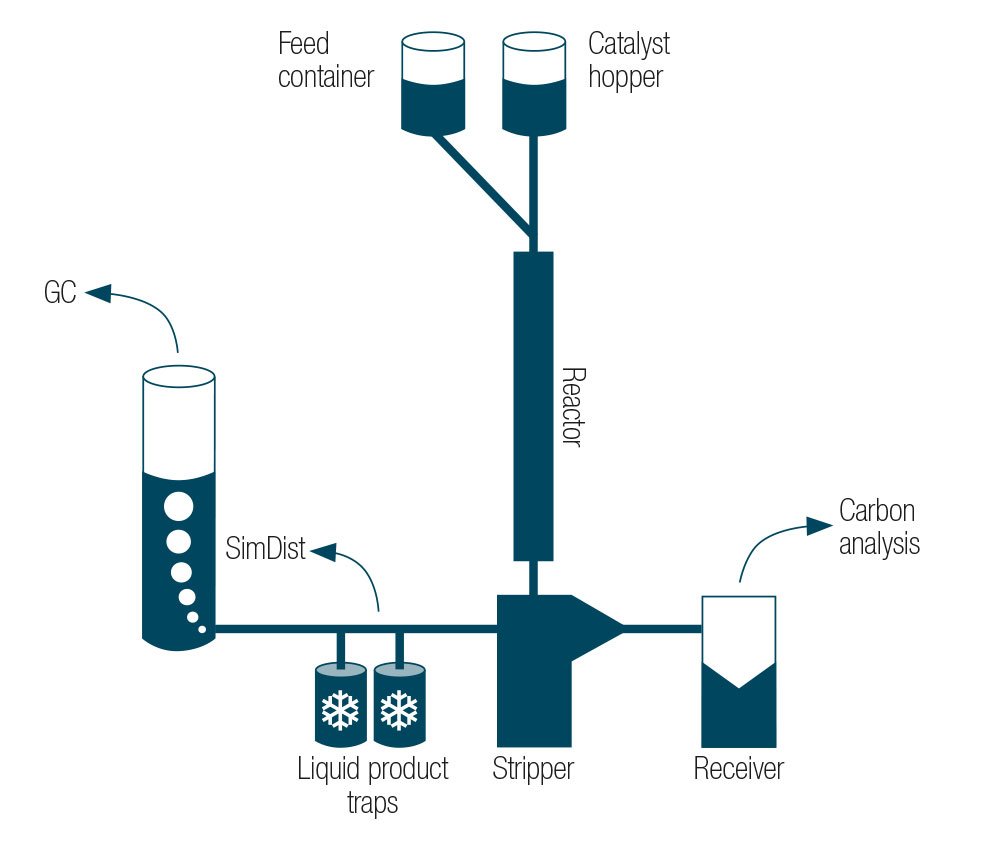

The micro downflow unit (MDU) is based on a lab-scale technology and offers an entrained catalyst flow reactor system analogous to commercial fluid catalyst cracking units (FCCUs). It can be operated within a wide range of process conditions, including elevated pressures which are typical for FCCUs. Furthermore, the MDU is fully automated and cost-efficient as only small amounts of catalysts and feeds are required. Processability of a broad range of feedstocks has been demonstrated, ranging from naphtha and vacuum gas oil to residue feeds and crude oils. It includes the latest software solution myhte™ for integrating, storing, retrieving, analyzing, and visualizing data.

Features of Micro Downflow Unit (MDU)

- Entrained flow reactor as commercial FCCU

- Pressures typical for an FCCU or a riser can be adjusted

- Since catalyst and feed move in the direction of gravity back-mixing is low

- Size, required material amounts, and operating expenditures in the range of laboratory methods

- Experiments at catalyst reactor residence times / contact times comparable to riser reactors

- Capability of simulating high severity operations (high cat-to-oil ratio)

- Cost-efficient (operation, catalyst, feedstock)

- Fully automated lab system

- 5 crackings per 8 hour shift w/ optional increase to 18 crackings per day

- Mass balances 98 +/- 2 %

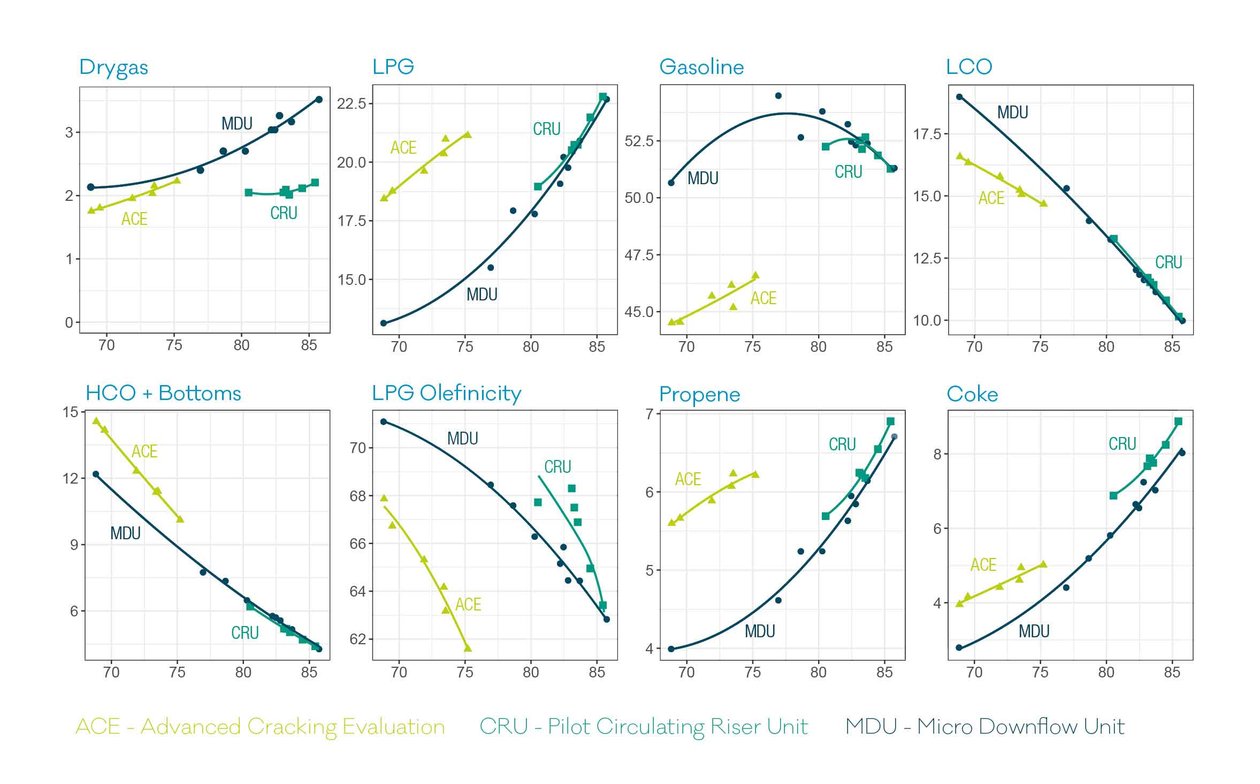

- Reproducible results matching well with circulating riser units and commercial FCCUs

- Flexible and broad parameter range

- Variety of feedstocks possible: VGO, high resid VGO, light cut naphtha, pyrolysis oils, biogenic feeds and full crude oil

- Feedstocks with CRC’s 0-10 % can be processed

Comparison of yields vs. conversion for ACE-CRU-MDU

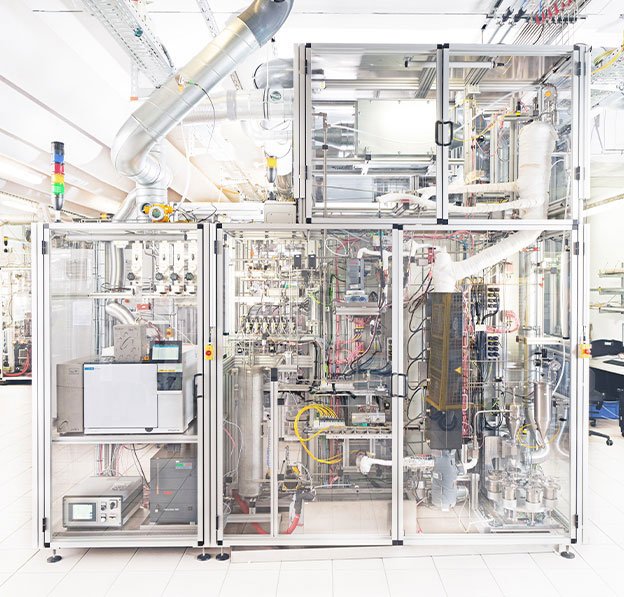

MDU infrastructure requirements

LABORATORY:

- Typical footprint 1.5 m x 3.5 m x 1.2 m (WxHxD) plus room for GC and PC workplace (height depending on the length of the reactor)

- Only local fume hood exhaust necessary

GAS SUPPLY:

- N2: 10 barg/100 barg

- Synthetic air: 10 barg

- House air: 10 barg

- GC gases: H2, He, N2, Ar

POWER SUPPLY:

- 400 VAC/5kW, other voltages upon request

Appearance and footprint of the downflow unit delivered may differ from the unit displayed.