Enhancing electrocatalysis R&D

The transition to a more sustainable and decarbonized energy future is one of the top challenges of our time. Electrocatalysis is a more energy efficient process and opens new paths that are not accessible through traditional catalysis, yet, whether for the production of hydrogen as a clean and sustainable energy carrier or for the reduction of CO2 to valuable products based on renewable energy.

High Throughput Experimentation (HTE) has proven to be the most efficient tool to accelerate the development of new catalytic processes and to ensure a short time to market for renewable products.

Electrochemical catalyst research

High throughput testing as a key to accelerate your R&D

APPLICATIONS

- Electrolysis

- Gap or zero gap

Water electrolysis (PEM, AEM, alkaline)

CO2 reduction reaction to products

Co-electrolysis

Fuel Cells

Redox flow batteries

Electrochemical pumps

YOUR BENEFITS

- Short time to market for new products and processes

- Enabling fast decision making and risk minimization

- Faster assessments of material stability and activity under application-relevant conditions (incl. accelerated aging protocols)

- Process optimization

- State-of-the-art methodology in high throughput testing is transferred into electrocatalysis trough:

- Parallelization | Standardization | Digitalization | Data management | Automation | Flexibility

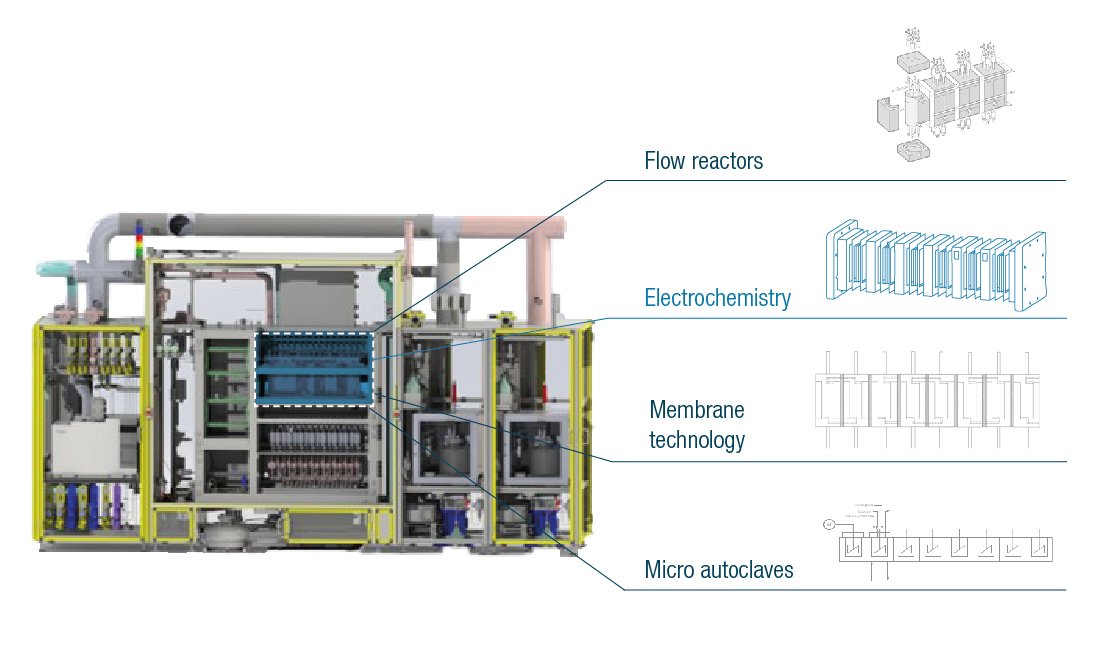

Broad range of technologies under one roof

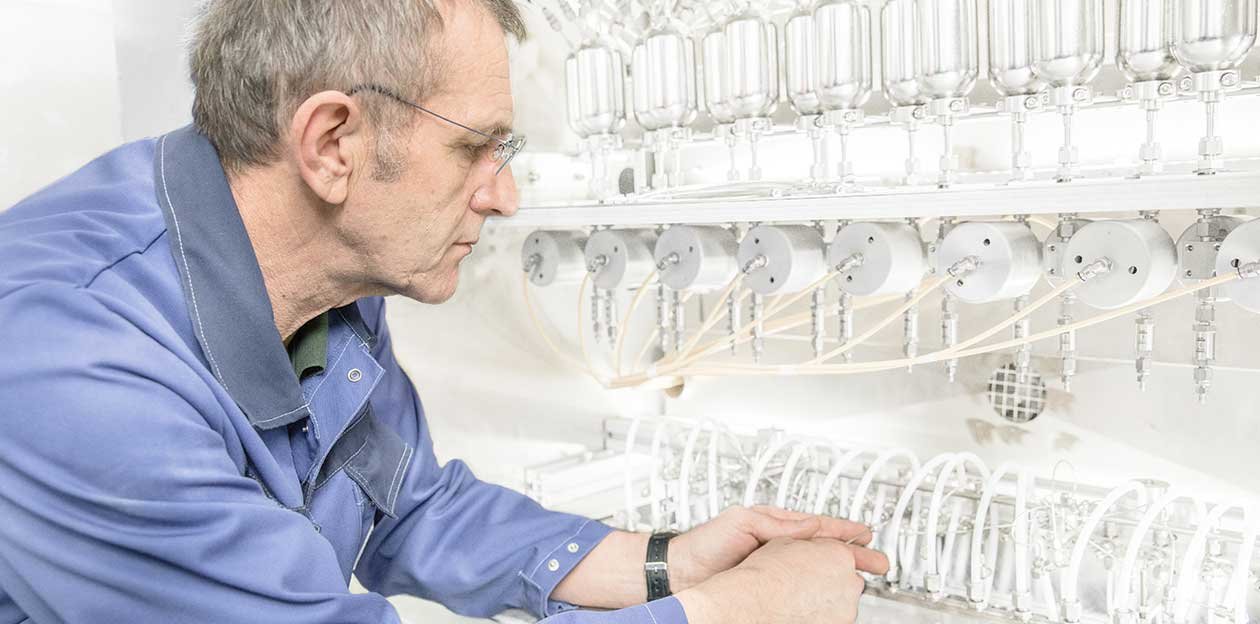

Over the past 20 years hte has build up great expertise in the development of high throughput technology and catalyst testing. The high throughput platform for different applications is therefore transferred from existing screening platform for catalysis into the field of electrochemistry and hydrogen generation.

The design and construction of our test systems is based on a modular concept which delivers a range of benefits on three levels of experimentation: test system, electrochemical cell and data workflow.

One significant advantage of our modular approach is the flexibility and parallelization it offers. As each module is designed to fit seamlessly with others, we can easily customize the testing unit according to specific needs. Whether it's adjusting the size, capacity, or functionality, our expertise and variety of units enable us to tailor the configuration precisely to meet customer requirements.

Another advantage is the optimization of lab footprint (e.g. L-form or in parallel). By using modular units, we can maximize the utilization of available space in the laboratory.

Our modularization allows for a straight forward extension of the test system at a later stage. For instance a 4-fold unit can be upgraded to a 8-, 12- or 16-fold test system depending on potential increasing capacity needs.

Discover more about our solutions in electrochemistry

CONTACT US

Dr.-Ing. Sara Claramunt

Business Development Manager

T +49 6221 7497 351

E sara.claramunthte-company.de

NEWS WITH RESEARCH CENTER JÜLICH

hte provides high throughput system for electrolysis to Research Center Jülich