Battery materials

Accelerated battery materials R&D

High throughput experimentation is a key to faster and more efficient R&D. It can give battery material producers and cell manufacturers a competitive edge by minimizing the time to market for new innovations.

hte is a leading provider for battery materials, catalysis and process development with more than 20 years experience in industrial R&D for global blue chip customers. Digitalization has always played an important role in our offering and is critical for the parallelization and automation of laboratory workflows. Our solutions are based on our unique high throughput mindset and are always tailored to the customers specific requirements. Our offering spans from consulting and joint developments to validated hardware products.

The aim will always be to allow for:

- Preparation and screening of large sample numbers withscalable unit operations

- Reduction of time and costs

- Fully automated operation, sampling and data tracking

- High degree of reproducibility and flexibility

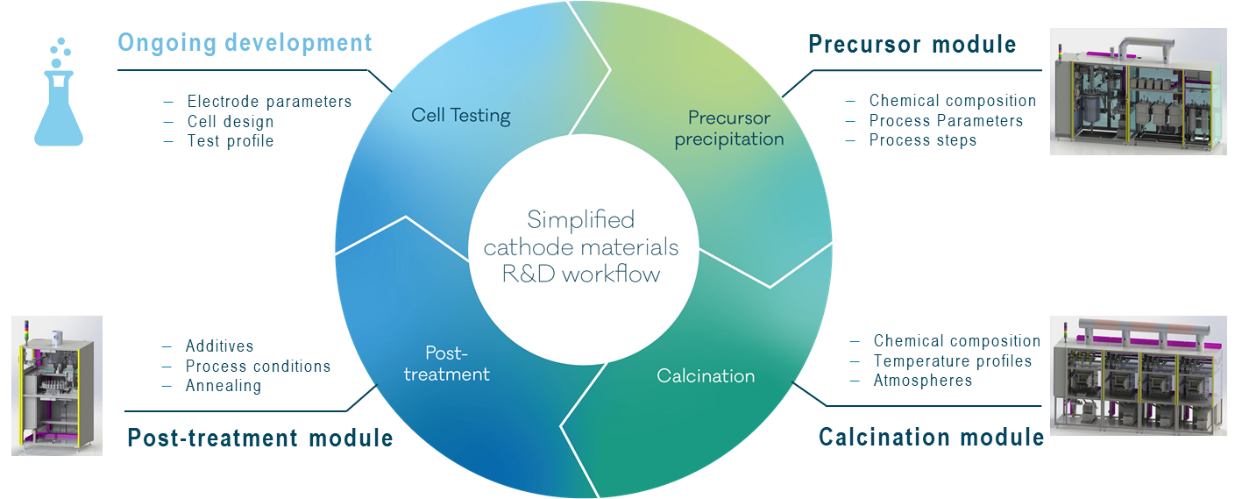

hte’s cathode material workflow illustrates our R&D approach

Closing the circle from material preparation to cell testing.

The performance of battery materials in a cell is a function of numerous interdependent parameters. Automated laboratory workflows allow the recording of huge amounts of process data during synthesis and screening to comprehensively describe these parameters. The key to successful and target oriented research is in the management of this data. hte provides tailor made software solutions to make this data available for advanced analysis and value creation.

Cathode material precursor synthesis

- Easily switchable between batch and continuous precipation mode

- Fully automated operation

- Precise control of process parameters with user-friendly software with automated data tracking

Dosing up to 8 individual feeds with high precision including composition variations over time for core-shell or gradient materials

Calcination of cathode materials

- Rig mounted lab-in-lab solution including safety sensors

- Calcination of up to 144 samples in parallel at individual temperatures

- High temperature resolution

- Flexible control of process conditions

Post-treatment of cathode materials

- Automated washing / wet treatment of up to 48 samples per run

- Reproducible washing procedures with up to 4 different washing solutions

- Barcode system to determine individual procedures

- Automated data recording

CONTACT US

Dr.-Ing. Sara Claramunt

Business Development Manager

T +49 6221 7497 351

E sara.claramunthte-company.de

CONTACT US

Dr. Charlotte Fritsch

Business Development Manager

T +49 6221 7497 429

E charlotte.fritschhte-company.de

News with FBICRC

Press Release

hte equips FBICRC project with precipitation unit for battery materials research

TECHNOLOGY SOLUTIONS

Reliable, turnkey ready systems

for establishing your own

high throughput workflows