Dry Reforming of Methane

Reduction of carbon footprint by sustainable syngas production from biobased and fossil CH4 and CO2

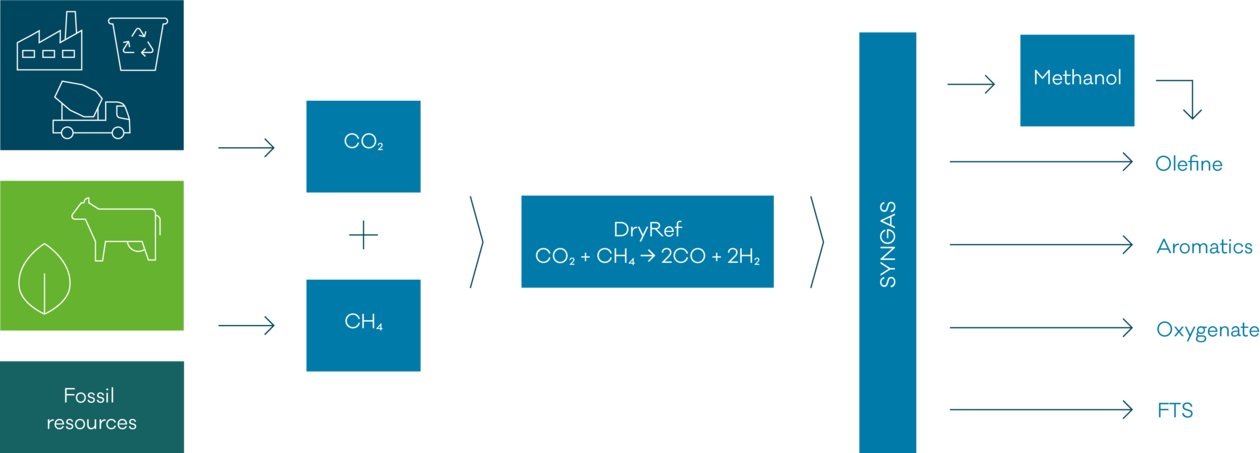

CH4 and CO2 are both greenhouse gases, which can be converted to CO rich syngas via dry reforming. Sources of methane can be renewable, e.g. derived from ruminant digestion and manure management associated with domestic livestock, waste or biomass. In addition other sources like fossil resources, e.g. natural gas or coal can be applied.

Compared to syngas production via steam methane reforming, dry reforming can be operated at low or even negative carbon footprint, since significant volumes of CO2 are consumed in the process. Since fossil and renewable feedstocks can be used, dry reforming might play an important role in the transition of the chemical industry. The produced CO rich synthesis gas can be used in established syngas conversion processes like methanol production, dimethyl ether (DME) or acetic acid synthesis. Due to the low H2:CO ratio it might be necessary to increase the H2/CO ratio in a subsequent process step or to add renewable H2 to the product stream.

What are the challenges in dry reforming of methane?

First, dry reforming of methane is still at an early stage compared to well-applied syngas generation technologies like steam reforming of methane, auto thermal reforming, or partial oxidation of methane. The supply of sustainable feed might be decentralized where fossil derived feed will be converted in industrial scale. Therefore, cost-efficient processes in small as well big scale need to be developed.

The supplied CH4 and CO2 will come from manifold sources with a manifold range of impurities. This requires gas separation and purification techniques, or a new generation of catalysts with sufficient activity, selectivity, and stability. So far, the catalyst development is still at the beginning. The challenges are mainly connected to catalyst deactivation by coking since dry reforming is done in the absence of water, known for inhibition of coke formation.

How can hte support your research in the area of dry reforming of Methane?

hte has already supported BASF and Linde in development of their DRYREF™ process and SYNSPIRE™ catalysts. We support our customers in catalyst development as well as process and tech service support of dry reforming demonstration plants as well as competitive catalyst testing and quality control. Stability studies of the catalyst and testing under industrially relevant conditions can be carried out. Further, we can provide you expertise in synthesis gas conversion chemistry (Fischer-Tropsch, methanol, DME, higher alcohols) to help you finding the optimum.

Scientific literature overview of academic and industrial DryRef applications

K. Wittich, M. Krämer, N. Bottke, S. A. Schunk,

“Catalytic Dry Reforming of Methane: Insights from Model Systems”

ChemCatChem, 2020, 12, 2130-2147. DOI.

A. Giehr, L. Maier, S. A. Schunk, O. Deutschmann,

“Thermodynamic Considerations on the Oxidation State of Co/γ-Al2O3 and Ni/γ-Al2O3 Catalysts under Dry and Steam Reforming Conditions”

ChemCatChem, 2017, 10, 751-757. DOI.

M. Usman, W. M. A. Wan Daud, H. F. Abbas,

“Dry reforming of methane: Influence of process parameters - A review”

Renew. Sust. Energ. Rev. 2015, 45,710–744. DOI.