Generating Knowledge

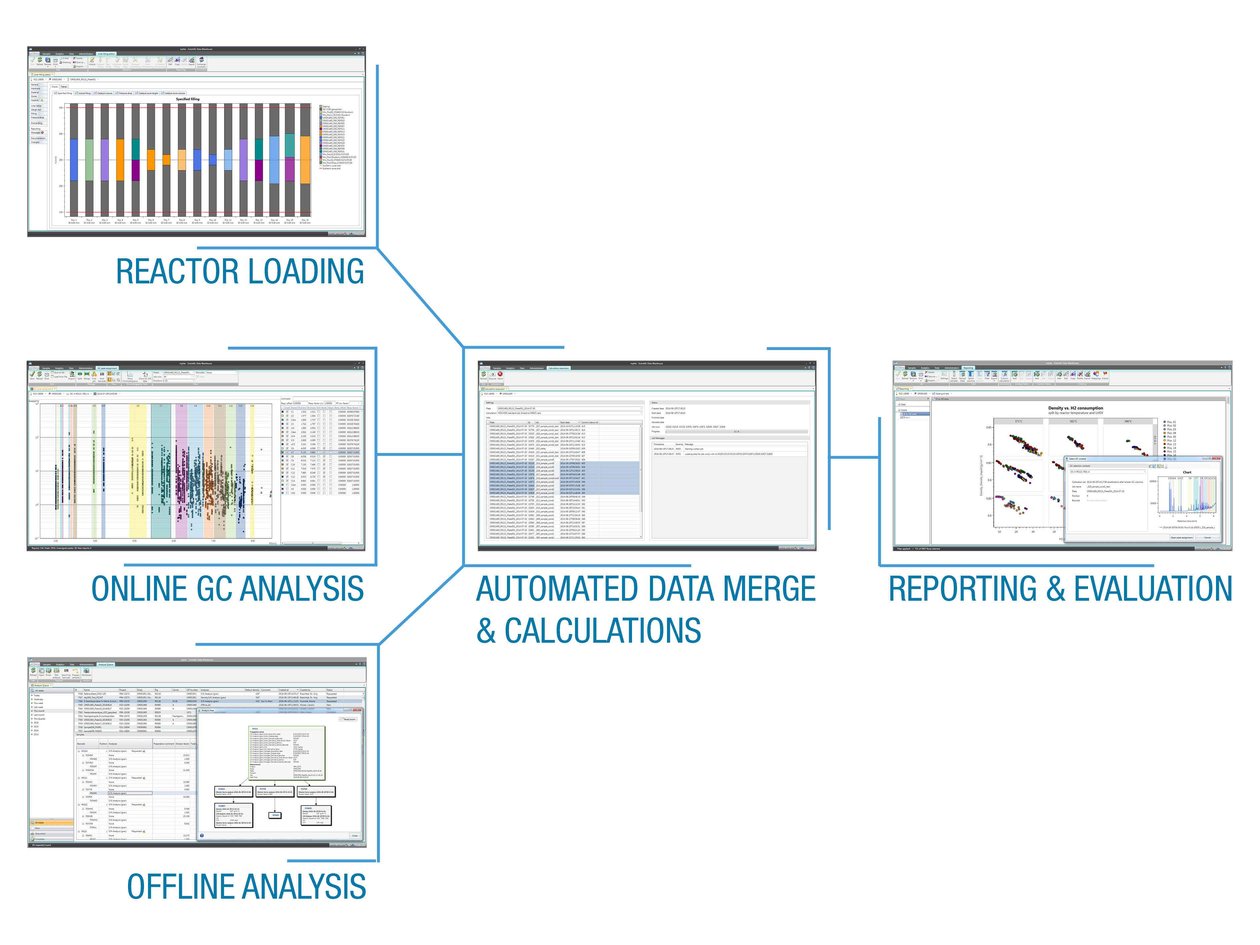

All steps of the high throughput workflow are supported and enabled by hte's software solution myhte™. The powerful data management software retrieves, integrates, stores, analyzes, and visualizes data generated within the workflow. It connects huge amounts of online and offline analytical data with experimental context and synthesis parameters in one database, allowing the researcher to optimize the design of the experiment in the next workflow step.

Features

- Structured storage and processing of all data generated during the catalyst testing workflow (data from catalyst synthesis, reactor loading, testing, and Analytics, such as calcination temperature, bulk densities, filling levels, reactor temperature, product mass flows, density values of liquid products)

- Powerful reactor loading workflow including embedding methods, stacked beds, and mixtures

- Efficient massive parallel batch evaluation of on- and offline GCs (interactive peak assignment and quantification)

- Request management, processing, and storage of offline analyses (e.g. BET, XRD, XRF, SimDis, S/N)

- User-adjustable data processing and calculation routines (calculation of conversions, yields, selectivity, and many more)

- Powerful and flexible reporting as well as visualization tools with drill-down capabilities

- Customized import and export functionalities into Microsoft PowerPoint, Word, and Excel, and other 3rd party software systems

Benefits

- One central database: The integration of all data in one database enables data to be queried quickly and centrally without compiling them manually from fragmented files, databases, or third-party applications.

- Visualization of the entire catalyst testing workflow in one application whereby all process steps can be fully tracked and evaluated.

- Standardized and central data management ensures completely transparent reproducibility of all data and faster fault detection with conspicuous data points.

- Quality controls enable fast fault correction by using all available context information (e.g. drift detection with gas chromatograms).

- Connecting the sample history with performance parameters enables a structure-effect correlation.