hte for Environmental Catalysis

New materials for efficient catalytic converters

hte provides high throughput catalyst development services in various fields of automotive and stationary exhaust aftertreatment. Thanks to automated catalyst synthesis capabilities, proprietary parallel catalyst testing systems, and deep application expertise, we accelerate the development of advanced catalyst solutions for automotive exhaust emission control.

OUR SOLUTIONS

- High throughput catalyst synthesis and aging

- Parallel testing in 48-fold units using small quantities of powders

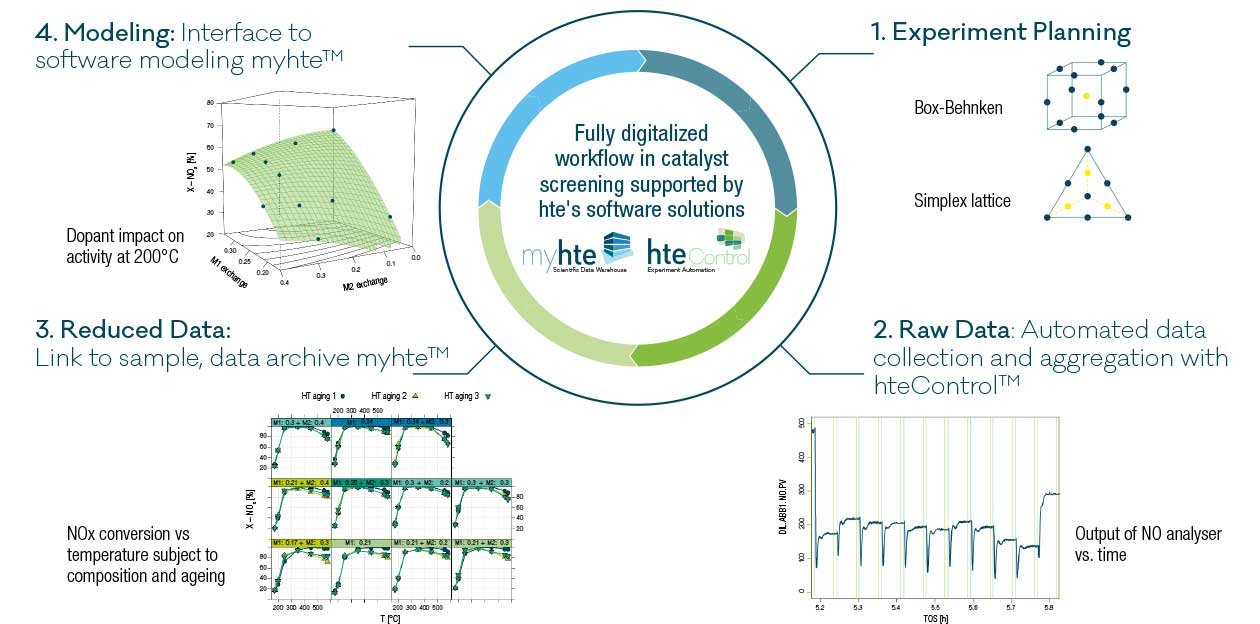

- Fully automated and computer-controlled 24/7 operation with hte’s software solution hteControl

- Additional core test unit for monolith samples

- Cold start test unit for dynamic test protocols

- Online analytics (incl. FTIR, MS analyzers)

- Integration into hte’s software solution myhte for data acquisition, processing, and reporting

- Fully integrated workflow for R&D projects

YOUR BENEFITS

- Combination of high throughput testing with statistical tools like DoE allows screening of large parameter spaces

- Simplified experiments save time and costs compared to engine bench or vehicle testing

- Scientific consulting and data interpretation

TYPICAL R&D USE CASES

- Primary screening of new materials

- Optimization of washcoat/catalyst composition

- Accelerated testing under realistic conditions

Testing technology

Typical 48-fold parallel reactor system

Overview test protocols

| Topic | Performance characteristics/protocols | Typical throughput (samples/week) | Data output (data points/week) |

|---|---|---|---|

| DOC | Light-off performance (CO/HC/NO) and sulfur resistance 2-5 light-off runs per sample | 45-135 | 4,500 - 11,250 |

| SCR | Low and high temperature SCR performance 4 protocols (standard and fast SCR, ammonia oxidation, and storage) | 30-45 45-135 (w/o NH3 storage) | 2,800 - 4,200 |

| TWC | Oxygen storage capacity (OSC) Catalytic performance: light-off, λ-sweep for CO/HC/NO | 225 45-90 (L/O and λ-sweep) | 900 6,000-12,000 (L/O and λ-sweep) |

| LNT | NOx efficiencies (lean/rich and lean) and NOx storage (lean) at 3 temperatures, 5 cycles per position, 2 sample loads | 45 | 1,800 - 2,700 |

| Flexible use for various automotive and stationary applications |

|---|

| Easy change of operation modes, cross-validated test protocols |

| DOC, SCR, LNT, TWC, PNA |

| Stationary DeNOx, CH4 oxidation, N2O abatement |

CONTACT US

Dr. Charlotte Fritsch

Business Development Manager

T +49 6221 7497 429

E charlotte.fritschhte-company.de