rWGS

Reverse Water Gas Shift Reaction (rWGS)

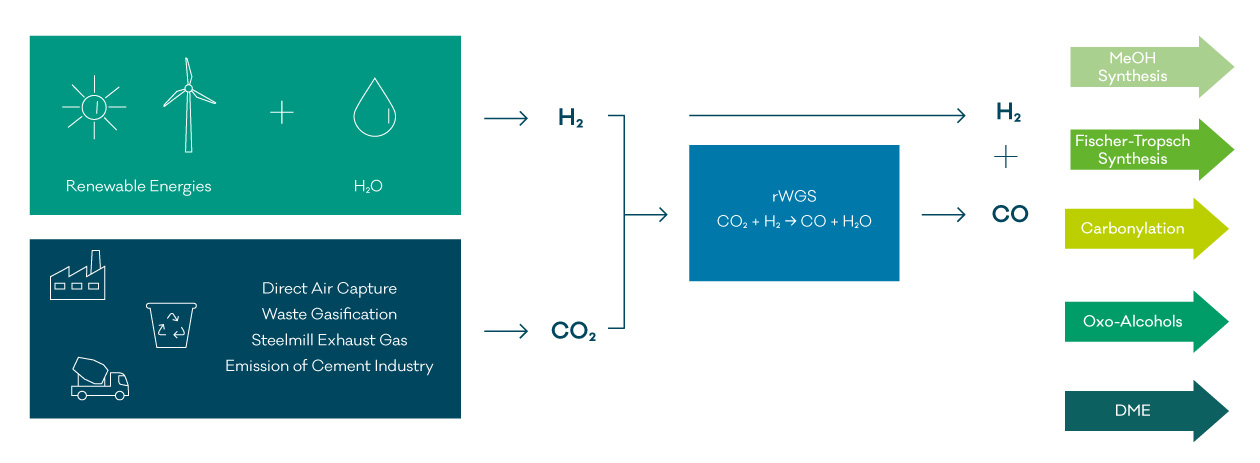

Utilization of CO2 from air or flue gas for syngas production

Mitigation of climate change and reduction of CO2 emissions are urgent topics on the political agenda. In 2019, the European Union passed its vision of a sustainable economy by presenting “The European Green Deal”. The main goal is to achieve climate neutrality by 2050.

One of the main drivers for climate change is the release of CO2 stemming from fossil based raw materials and products into the air. Several approaches for the reduction of CO2 emissions are currently under development. A promising approach to reduce CO2 emission is the hydrogenation of CO2 via the reverse water gas shift reaction and utilization of the generated syngas in the established syngas conversion processes.

For an effective reduction of the carbon footprint, the H2 must be produced from renewable sources, such as wind and solar powered water electrolysis and CO2 must be supplied from sustainable resources like waste disposal or industrial processes such as steel or cement production, or directly from air.

What are the challenges in the reverse water gas shift reaction?

First and foremost, the production of green H2 on a sufficiently large scale is still not established. The cost-efficient supply of hydrogen from low carbon electricity will be playing a key role in the successful application of sustainable rWGS in the chemical industry. The utilized CO2 is present only in low concentrations in the gaseous feedstocks and contains a range of impurities. This requires gas separation and purification techniques, or a new generation of catalysts with sufficient activity, selectivity, and stability. So far, the catalyst development is still at the beginning. Several catalysts are under discussion like K-Mo2C, Ni/SiO2 or Pt/TiO2. The challenges in catalyst development are comparable to steam methane reforming catalyst, where hydrothermal ageing and coking are important deactivation mechanisms.

How can hte support your research in the area of reverse water gas shift reaction (rWGS)?

hte supports its customers in process and technical service support of rWGS demonstration plants as well as competitive catalyst testing and quality control. Deactivation studies of the catalyst and testing under industrially relevant conditions can be carried out. Further, we can provide you our extensive expertise in synthesis gas conversion chemistry (Fischer-Tropsch, methanol, DME, higher alcohols) to help you finding the optimum use of the renewable CO feedstock.

Scientific literature overview of academic and industrial rWGS applications

Y. A. Daza, J. N. Kuhn,

“CO2 conversion by reverse water gas shift catalysis: comparison of catalysts, mechanisms and their consequences for CO2 conversion to liquid fuels”

RSC Adv., 2016, 6, 49675-49691. DOI.

M. Juneau, M. Vonglis, J. Hartvigsen, L. Frost, D. Bayerl, M. Dixit, G. Mpourmpakis, J. R. Morse, J. W. Baldwin, H. D. Willauer, M. D. Porosoff,

“Assessing the viability of K-Mo2C for reverse water–gas shift scale-up: molecular to laboratory to pilot scale”

Energy Environ. Sci., 2020, 13, 2524–2539. DOI.

T. S. Galhardo, A. H. Braga, B. H. Arpini, J. Szanyi, R. V. Gonçalves, B. F. Zornio, C. R. Miranda, and L. M. Rossi,

“Optimizing Active Sites for High CO Selectivity during CO2 Hydrogenation over Supported Nickel Catalysts”

J. Am. Chem. Soc.,2021, 143, 4268−4280. DOI.

B. Mutz, C. Hauber, P. Kolb, and M. Weber

“rWGS as a key step to transform CO2 into valuable products - accelerated R&D applying advanced high throughput technology”

Presentation at the DGMK conference "Catalysis for the energy transition" 2022, download