Methanation

Synthetic natural gas (SNG) from carbon dioxide

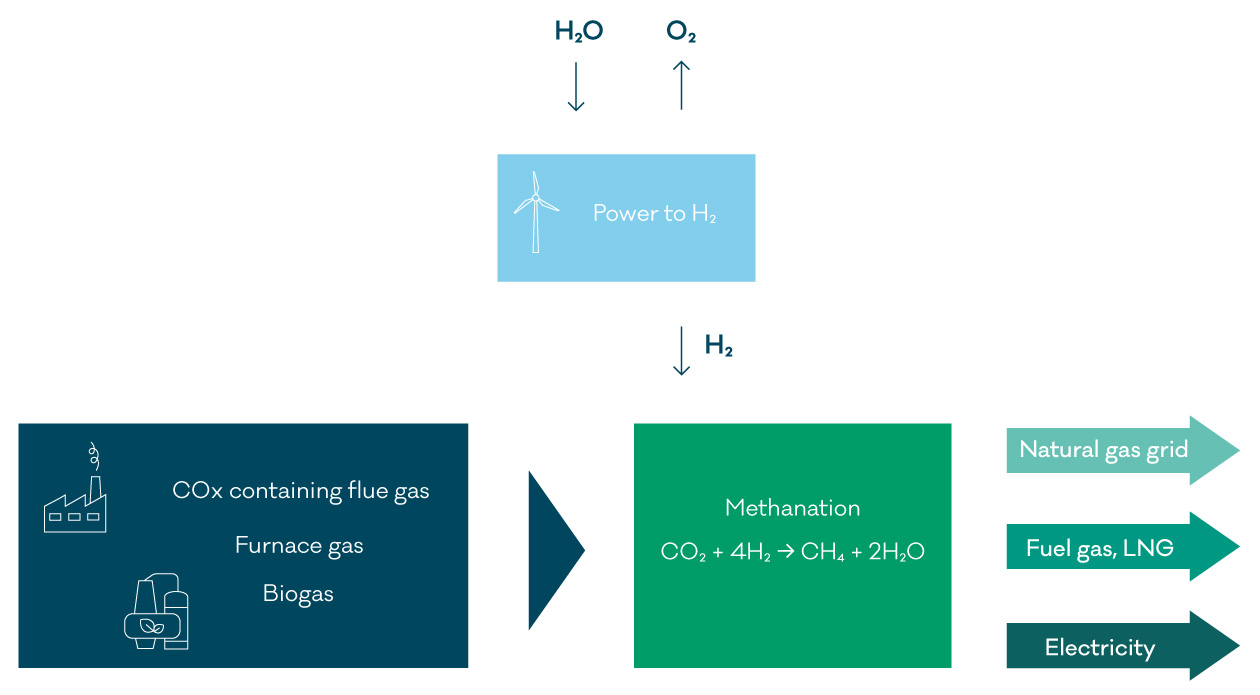

Methanation as a tool for upgrading CO/CO2-containing flue gas streams from industrial plants to synthetic natural gas (SNG) while reducing their carbon footprint.

Within the power-to-gas concept, renewable H2 is produced from wind and solar powered water electrolysis and further utilized for the catalytic methanation of CO and CO2.

SNG serves as a long-term energy carrier e.g. for grid stability in future power systems, where the fluctuating supply of renewable energies has to be matched with power demand temporally and locally by re-converting SNG into electricity. Furthermore, renewable methane is suitable as CO2 neutral fuel for heavy-duty traffic, e.g. LNG-trucks continuing to use the well-developed combustion engines.

One big advantage is the existing infrastructure, since SNG can be injected, distributed and stored in the wide-ranging natural gas grid. This also allows the production of SNG in small, decentralized plants.

What are the challenges in the methanation of industrial off-gas?

The hydrogenation of pure CO or CO2 feeds to SNG is well developed. However, utilizing industrially relevant feedstocks and process conditions to deliver pipeline quality SNG, as in the methanation of raw biogas, flue or furnace gas (e.g. from steel or cement production), appropriate catalyst and process design is required. Usually, effluent gas of such applications contains mixtures of CO and CO2 featuring a wide range of compositions that need to be converted to SNG. High shares of CH4 can already be included in the feed for methanation that needs to be considered.

In addition, trace components are present which can harm the active site of the catalyst through poisoning, oxidation or coking. The catalysts face various challenging process conditions in process integrated methanation reactions. Depending on the process steps in front or behind the methanation reactor, SNG has to be produced in unfavorable parameter space regarding temperature, pressure and severity that may lead to sintering of the metal nanoparticles and degradation effects of the catalyst. Therefore, it is crucial to test the catalysts under industrially relevant conditionst to evaluate their performance and stability.

How can hte support your research?

hte supports its customers in process and tech service support of methanation demonstration plants as well as competitive catalyst testing and quality control. Investigating the catalyst stability, lifetime as well as root-cause of deactivation under industrially relevant process conditions and feedstocks are of great importance. The preparation of novel material formulations and catalyst screening broadens our competences.

Scientific literature overview of industrial methanation applications

1000 h biogas methanation in Denmark has recently been published by Dannesboe et al. The direct catalytic upgrading of biogas was demonstrated to be ready for industrial scale implementation to deliver pipeline quality gas. A status review about power-to-gas including electrolysis and methanation was reported by Thema et al. 153 completed, recent and planned pilot and demonstration projects worldwide since 1988 are summarized in this report. An overview of developed methanation catalysts and reactor concepts is given by Ashok et al. Development of bimetallic catalysts, benchmarking and kinetic investigations was performed by Mutz et al. for CO2 methanation within academia research.

C. Dannesboe, J.B. Hansen, I. Johannsen,

“Catalytic methanation of CO2 in biogas: experimental results from a reactor

at full scale”

React. Chem. Eng., 2020, 5, 183-189. DOI.

M. Thema, F. Bauer, M. Sterner,

“Power-to-Gas: Electrolysis and methanation status review”

Renew. Sustain. Energy Rev., 2019, 112, 775-787. DOI.

J. Ashok, S. Pati, P. Hongmanorom, Z. Tianxi, C. Junmei, S. Kawi,

“A review of recent catalyst advances in CO2 methanation processes”

Catal. Today, 2020, 356, 471–489. DOI.

B. Mutz, M. Belimov, W. Wang, P. Sprenger, M.-A. Serrer, D. Wang, P. Pfeifer, W. Kleist, J.-D. Grunwaldt,

“Potential of an Alumina-Supported Ni3Fe Catalyst in the Methanation of CO2: Impact of Alloy Formation on Activity and Stability”

ACS Catal., 2017, 7, 6802-6814. DOI.